Success StoriesPractical

2026年1月7日

How to Choose the Right Injection Mold Manufacturer for Your Project?

In the plastic injection molding industry, the quality of the mold directly impacts product precision, production efficiency, and overall market competitiveness. This is especially true for projects t

In the plastic injection molding industry, the quality of the mold directly impacts product precision, production efficiency, and overall market competitiveness. This is especially true for projects targeting European and American markets, where molds must adhere to strict international standards and compliance requirements. Selecting a reliable injection mold manufacturer is not just about forming a partnership—it's a critical factor in your project's success.This guide breaks down the key considerations to help you find the perfect partner that aligns with your needs. We'll also highlight a trusted expert in export-grade molds for Europe and the US: JST Mould (website: www.jstmold.com).

1. Prioritize Compliance and Certifications for Your Target Market

The foundation of a successful export project starts with regulatory compliance.

- Essential Certifications: Look for manufacturers with ISO 9001 quality management certification. For medical products, seek ISO 13485. Additional credentials like UL certification for plastic materials are valuable. JST Mould holds ISO 9001 certification and provides full compliance documentation, ensuring smooth entry into European and US markets.

- Material and Process Compliance: Markets in Europe and the US demand high standards for environmental safety, weather resistance, and material quality. Verify that the manufacturer uses mold steels compliant with RoHS and REACH regulations (such as S136 or H13) and maintains robust environmental controls in their processes.

2. Assess Technical Expertise and Production Capabilities

True excellence comes from advanced technology and precision manufacturing.

- Design Capabilities: Leading manufacturers offer 3D modeling (SolidWorks, UG) and mold flow analysis (Moldflow) to predict and resolve issues like filling, cooling, and shrinkage early—minimizing trial runs. JST Mould's experienced design team delivers tailored solutions for complex structures common in high-end European and US projects.

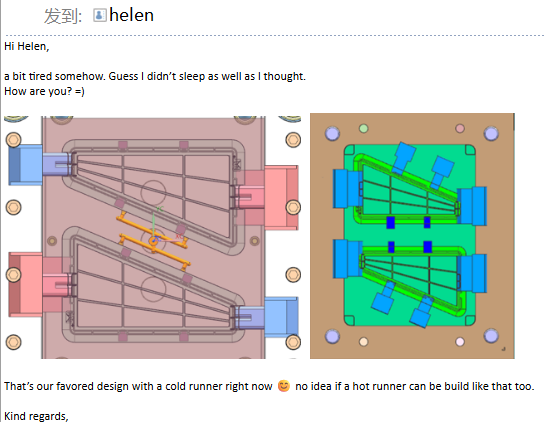

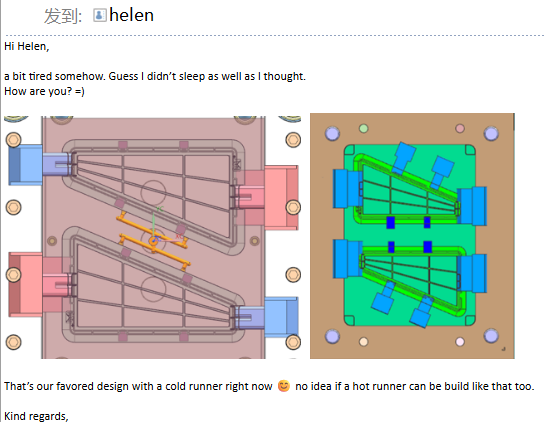

Case Study:

Fig.1

Fig.2

Fig.3

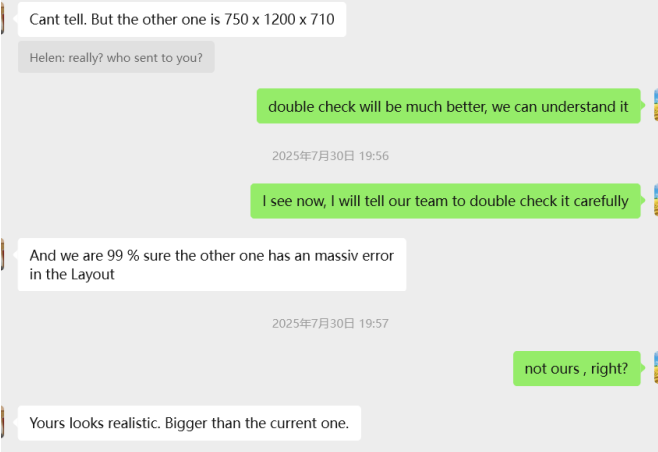

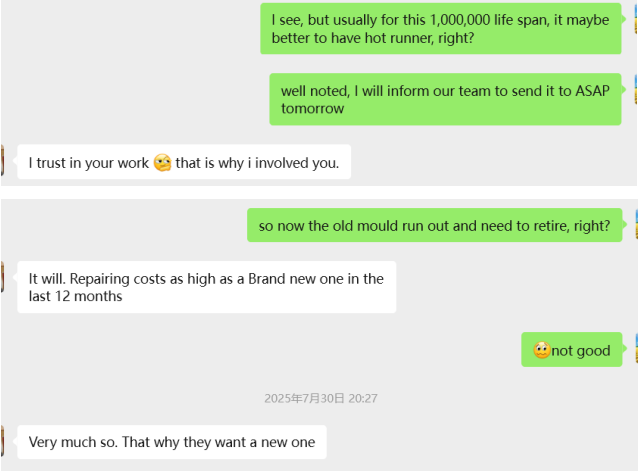

From the case, we can learn that the left one of mold layout was wrong, in order to make smaller size of the mold and save mold base costs, then choose cold runner. Yes, it did save some costs of the manufacturing stage, but it also resulted in disaster in the later mass production.

It always “Strike”, you need to repair it, in one way, same as our this European customer, you need to pay repairing costs as high as a Brand new one in the last 12 months. And you prefer to buy a new one rather than to repair it. If so, it costs you double costs of the tools.

On the other way, if the mold couldn’t work, it will stop the production, which will delay the parts delivery to your customers or delay new products launching to market. What are the worse result can you image? This will make you loss lots of money too.

As a reliable mold maker, our team will discuss all the possible design schemes before submitting the best solution to our customer because we are responsible and experienced.

- Processing Equipment: High-precision molds require state-of-the-art machinery. Verify the presence of CNC machining centers, EDM (electrical discharge machining), WEDM (wire cutting), high-speed milling, and precision levels meeting Western standards (e.g., ±0.005mm tolerance). JST Mould utilizes imported advanced equipment in standardized workshops to guarantee consistency and accuracy.

- Inspection and Quality Control: A comprehensive testing system is non-negotiable. Look for coordinate measuring machines (CMM), hardness testers, surface roughness instruments, and full-dimensional checks on critical components like cores, cavities, and ejector pins. JST Mould implements rigorous multi-stage inspection protocols, ensuring every mold meets stringent European and US quality expectations before shipment.

3. Evaluate Real-World Experience and Industry Relevance

Past performance is the best indicator of future success.

- Project Case Matching: Ask for experience with similar products and industries (e.g., automotive parts, medical devices, consumer electronics). Request case studies, mold samples, and client references—especially from leading European or US companies. JST Mold specializes in export molds, serving clients across automotive, medical, and consumer electronics sectors with proven track records.

- Mold Lifespan Guarantees: Depending on production volume, confirm commitments such as 500,000 shots for standard molds or over 1 million for premium ones, plus warranty programs.

4. Demand Strong Service and After-Sales Support

Injection molding partnerships are long-term—full lifecycle support is essential, particularly for international projects.

- End-to-End Service: Top manufacturers provide one-stop solutions covering design, manufacturing, trial molding, mass production support, and even injection molding services if needed. JST Mould offers complete customized services for European and US clients, with dedicated account managers to overcome cross-border communication challenges.

- After-Sales Responsiveness: Clarify warranty periods, response times for issues, and options for on-site repairs or remote support. JST Mould maintains a rapid-response system tailored to overseas clients, minimizing downtime and ensuring smooth production.

5. Balance Cost, Value, and Delivery Reliability

Avoid compromising quality for low prices or risking delays that impact market launch.

- Transparent Pricing: Ensure quotes clearly break down design, machining, material, and trial costs without hidden fees. JST Mould provides clear, detailed quotations optimized for cost efficiency while meeting European and US standards.

- Delivery Control: Confirm realistic lead times and contingency plans for urgent projects. JST Mould uses standardized scheduling systems and flexible production planning to deliver on time, aligning with tight Western production timelines.

Recommended Partner: JST Mould – Your Expert in Export-Grade Injection Molds

As a dedicated injection mold manufacturer focused on European and US export standards, JST Mould www.jstmould.com excels across compliance, technology, production control, and service. Whether you need high-precision molds with complex geometries or long-life tools for high-volume production, JST Mould delivers customized solutions backed by years of international experience—making them a trusted choice for global enterprises.

Conclusion

Selecting the ideal injection mold manufacturer requires a balanced evaluation: compliance as the foundation, technical strength as the core, proven experience as validation, comprehensive service as support, and cost-delivery alignment for sustainability. For projects aimed at Europe and the US, prioritize manufacturers like JST Mould that deeply understand international standards and offer full-chain capabilities. This approach ensures project success from the start and fosters long-term, reliable partnerships.

If you're currently sourcing an injection mold partner for a European or US project, visit www.jstmold.com to explore case studies, view capabilities, or request a customized quote. Their professional team is ready to support your success.